Nos produits

Nos produits offrent des performances de durée de vie comparables à celles de la galvanisation à chaud dans les mêmes conditions environnementales.

Les Avantages de la technologie Rust-Anode

- Agit comme un couplage actif avec l'acier et crée une liaison électrochimique qui entraîne une protection active (mV) dans la même gamme que la galvanisation à chaud ou la métallisation

- Une véritable protection active et sacrificielle comme la galvanisation à chaud

- Exposition à la température -62°C à +120°C (-80°F à + 250°F)

- Sèche à l'humidité sans restriction du point de rosée

- Pas d'effets de distorsion des substrats par rapport à la galvanisation à chaud

- Soudable

- Séchage rapide

- Haute flexibilité

- Peut être recouvert par la plupart des peintures, et même par des peintures à la poudre

- Testé avec succès pour la toxicité sous le feu

- L'épaisseur du zinc peut être contrôlée pendant l'application ou après, avec des couches supplémentaires si nécessaire

- Zinc pur extra fin atomisé (pureté de 99,995%) permettant une plus grande densité de zinc et une anode performante

En savoir plus à propos de Rust-Anode®

Un de nos experts vous contactera pour vous accompagner.

Sélectionnez votre domaine d'application pour en savoir plus sur nos produits

Rust anode® primer

Depuis 1954, les produits RUST-ANODE® sont connus et appliqués dans plus de 50 pays ! Leurs caractéristiques supérieures les ont placés à l’avant-garde des solutions anti-corrosion. Approuvée par les principaux laboratoires officiels en Europe et adoptée par les forces de l’OTAN dès ses débuts, la technologie RUST-ANODE® s’est imposée comme un leader mondial pour garantir la protection active et la prolongation de la durée de vie des biens courants.

Questions et réponses

Oui, Rust-Anode est homologué pour recharger la protection en zinc de structures d’acier galvanisé à chaud ou de la métallisation. De plus, notre produit est homologué par le Ministère du Transport du Québec, de l’Ontario et du Canada, en plus d’être approuvé par Hydro-Québec (SN31.101 pour la maintenance des postes de distribution et TET-LIA-N-SUP0012 pour la maintenance des pylônes).

Rust-Anode offre une durée de vie comparable à la galvanisation à chaud ou à la métallisation dans les mêmes conditions d’exposition.

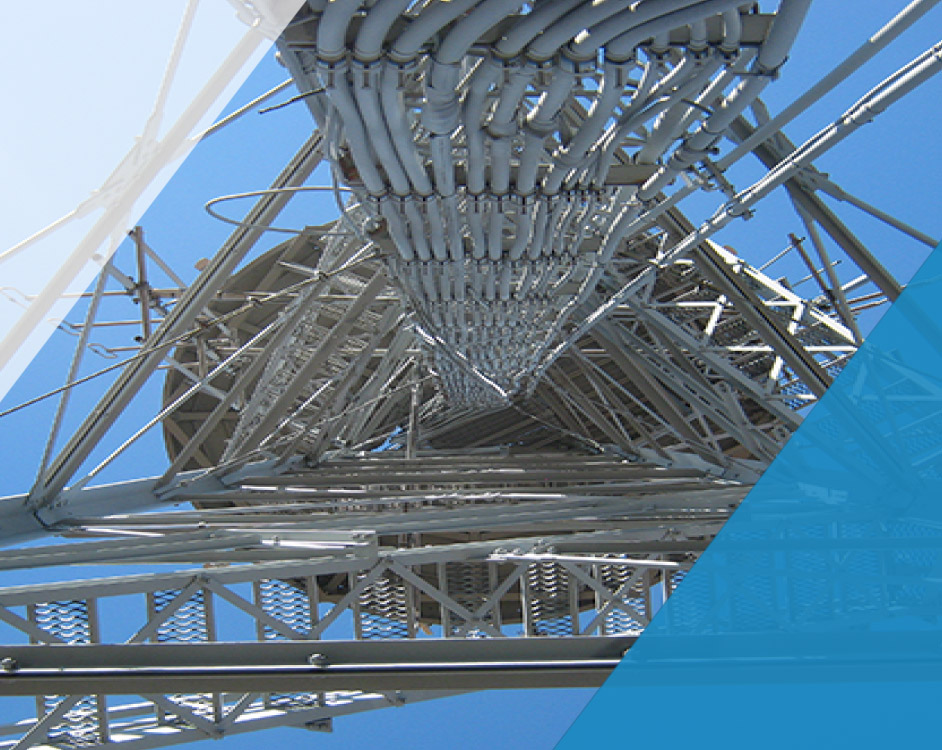

Ponts, maritime, tours de transmission électrique et ou de télécommunication, bâtiments, réservoirs, transport, camions-remorque, usine.

Formation gratuite

Reconnue par l’Ordre des Ingénieurs du Québec

Une formation / présentation gratuite (1 ou 2h) sur la corrosion de l’acier et du zinc avec attestation de formation est disponible sur demande.