The Importance of a Clear Specification:

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

If you have ever crossed a railway or contemplated a railway bridge, you may have noticed an intriguing phenomenon: their lack of paint. So why do these imposing metal structures remain devoid of any color? The answer lies in an exceptionally fascinating material: Corten steel. In this post, we will explore the mystery of unpainted railway bridges and the unique properties of Corten steel.

Unpainted Railway Bridges

The first question that often comes to mind is why railway bridges remain unpainted. Unlike ordinary steel, which requires protective paint against corrosion, Corten steel bridges are designed to withstand the outdoor environment without needing additional paint. Paint can trap moisture and debris, accelerating the corrosion process rather than slowing it down.

Corten Steel: An Elegant Solution

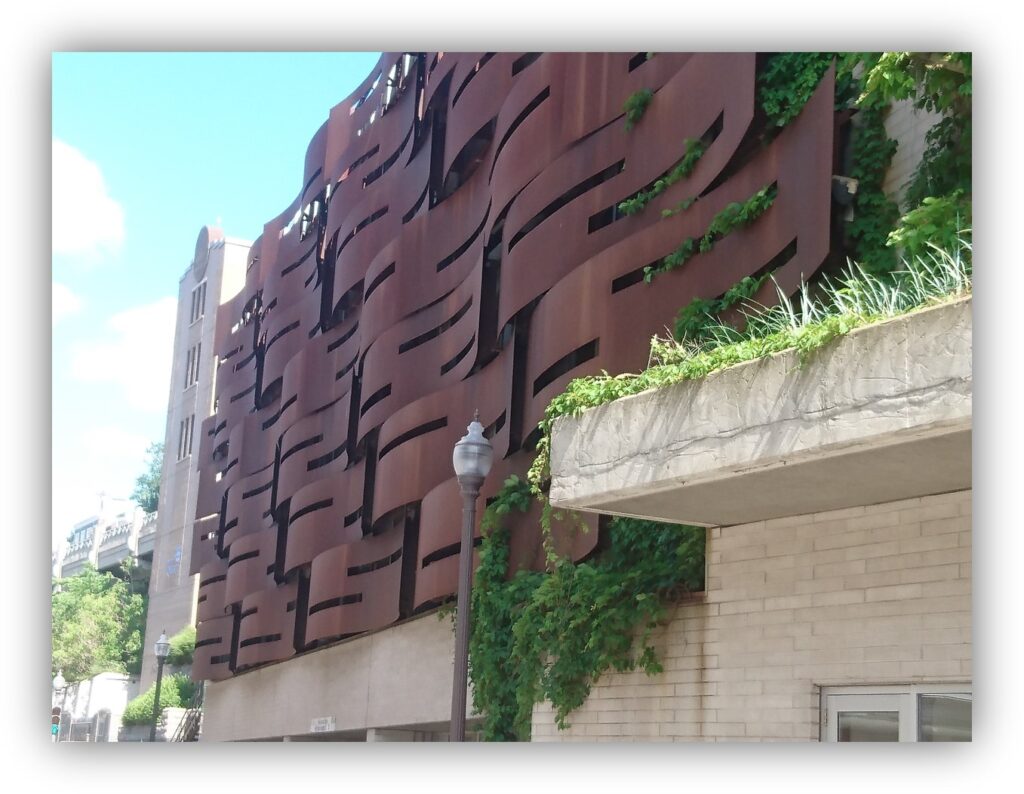

Corten steel, also known as weathering steel, is a specially formulated steel alloy that develops a protective patina layer when exposed to the elements. This steel is very thick and dense, making it highly resistant. This patina, which gives the steel its distinctive rust color, acts as a natural barrier against corrosion, offering long-lasting protection against weather and environmental damage.

Architects and artists use Corten steel for more decorative elements to create steel sculptures. In the United States, it is used to construct large power poles in southern states.

The Advantages of Corten Steel

Using Corten steel in railway bridge construction presents several advantages:

Environmental Considerations

Painting railway bridges requires the use of potentially harmful chemicals for the environment. By opting for unpainted structures, railway authorities can reduce their environmental footprint while maintaining the safety and durability of infrastructures.

Exposed to salts and constant humidity (Corten steel needs to dry to develop a patina), it does not work well if there is contact with humidity and contaminants (salt, chemicals, or others).

Another aspect is that with the weather, surface rust can stain other elements and create public concern about the integrity of the rusted component.

Corten steel can be coated, and Rust-Anode Primer is a solution to maintain these structures even longer.

Conclusion: The Elegance of Simplicity

In summary, the decision not to paint railway bridges is based on trust in the protective properties of Corten steel. This innovative material offers an elegant and effective solution to ensure the durability and safety of metal infrastructures while giving them a distinctive aesthetic. The next time you cross an unpainted railway bridge, take a moment to observe it.

The Rust-Anode® technology allows for on-site zinc recharging of new or used structures damaged by rust or corrosion and offers the same performance as hot-dip galvanization.

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

In 2024, Trifluvienne Pneus & Mécanique SL turned to Galvatech 2000 to extend the service life of their galvanized metal roof, which had been in

A sheet pile wall was installed for a new development project adjacent to a train yard. Covering approximately 22,000 square feet, the project team chose