Application areas

Select your application area to learn more about our solutions.

What we do

Since its establishment in 1954, RUST-ANODE® products have gained worldwide recognition and have been successfully implemented in more than 50 countries. Their exceptional characteristics have positioned them at the forefront of anti-corrosion solutions. Approved by renowned official laboratories in Europe, North-America, and embraced by NATO forces from the beginning, RUST-ANODE® zinc technology has firmly established itself as a global leader in delivering active protection and significantly extending the lifespan of various assets.

We aim to introduce our revolutionary technology to the world with great pride, showcasing its unparalleled effectiveness and wide-ranging applications.

Who we are

Galvatech is a well-known manufacturer of galvanizing coatings and the main distributor of Rust-Anode in North America, South America, and Europe. The 50,000 square feet facility includes a state-of-the-art specialized laboratory.

Galvatech is the main distributor in America and Europe for Rust-Anode SRL, a well-known manufacturer of galvanizing compound technologies. Our 50,000 square feet facility includes a state-of-the-art specialized laboratory.

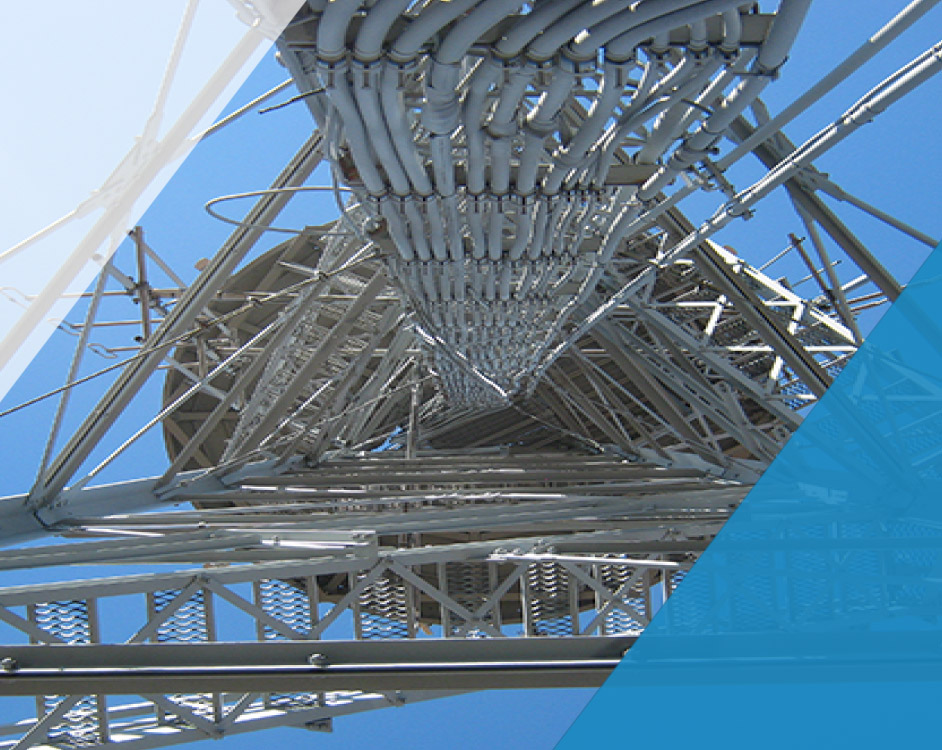

Our technology provides active cathodic protection to steel structures. The Galvatech zinc coatings are single-component products that fuse with the existing layers of zinc, recharging the cathodic protection of galvanized and metallic steel. Our revolutionary solutions are perfectly suited for use in workshops and construction sites.

Our anti-corrosion treatments act as an active layer on metal surfaces. The corrosion resistance performance of the technology is comparable to hot-dip galvanization (HDG) and significantly reduces maintenance costs for your assets compared to standard paints, making it an economical and effective solution.

Our unique technology enables:

- Superior corrosion protection

- Excellent barrier and sacrificial protection against corrosion

- Extended lifespan of maintenance programs

- Increases asset integrity lifespan and reduces maintenance costs

- Unique zinc-rich galvanizing coating

- Extra-fine atomized pure zinc (99.995% purity) for greater zinc density and high-performing anode

- Single-component that facilitates application

- Offers protection in the same range as hot-dip galvanization (HDG)

- Low VOC content, with an extremely low concentration of volatile organic compounds, making it more environmentally friendly

- Mouse gray zinc color

We offer you our services:

- Technical assistance with qualified technicians trained by NACE

- Collaboration with project leaders for the preparation of technical documents

- Training for the client's team to enhance their understanding of corrosion control mechanisms

- On-site and remote technical assistance for the application of RUST-ANODE® technology

Questions and answers

Rust-Anode offers a comparable lifespan to hot-dip galvanization or metallization under the same exposure conditions.

Bridges, maritime structures, electrical and telecommunication transmission towers, buildings, tanks, transportation, trailers, and factories.

Free Training

A free training/presentation (1 or 2 hours) on steel and zinc corrosion. A certificate of completion is available upon request.