Structures

Rust-anode primer

Technologie unique de galvanisation industrielle riche en zinc organique par liens électro-chimique avec 88% de zinc dans la couche sèche. Offre une durée de vie comparable à la galvanisation à chaud dans les mêmes conditions d’expositions

Formats disponibles : 0.5, 2 et 12 kilos

- Enduit mono composant

- Zinc organique pure a 99.995%

- Inférieur en C.O.V. que les normes américaines les plus sévères (Californie) 340 grams/litre

- Protection Cathodique par lien électrochimique avec le métal (résistance Wmesurable)

- Facile à appliquer, avec les équipements standards à peinturer, incluant l’électrostatique.

- Préparation requise de la surface: SSPC-SP7 ou SSPC-SP6 selon le cas, ainsi qu’à l’acide

- Peut-être appliqué sur de la rouille non friable, dont la poussière a été enlevée

- Peut recharger en zinc de l’ancienne galvanisation à chaud existante.

- Peut être recouvert par la plupart des peintures

- Rust-Anode® Primer a une seule couleur. Gris zinc naturel mat RAL # 7005

- À épaisseur égale, Rust-anode® primer, offre les mêmes performances que la galvanisation à chaud ainsi que la métallisation

- Aucune distorsion de structures.

- On peut souder sur Rust-Anode® Primer en dégageant moins de gaz toxiques ou flammèches.

- À des propriétés antifouling. (anti-coquillage en immersion)

- Haute résistance à l’eau salée et à l’environnement salin

- Peut-être applique sur de l’aluminium, ainsi que le béton et les peintures existantes après un nettoyage minimal

- Résiste aux hydrocarbures, comme l’huile hydraulique, le diesel, la gazoline, l’urée, etc.

- Sèche rapidement. (hygroréactif) à l’humidité.

- Sa surface peut être retouchée en tout temps par lui-même.

- Peut-être appliqué à des températures de –5°C à +37°C (23°F à +98°F).

- Rencontre les normes : ASTM B117 brouillard salin, ASTM D522 pliage, ONGC1-GP-71 méthode 119.5, et ONGC-1.181, Agence canadienne d’inspection des aliments

| Visualiser le document ici |

- Une élasticité et plasticité remarquable de la couche sèche qui autorise la dilatation ou le pliage du support;

- Il change peu de couleur dans le temps;

- Une adhésion totale et permanente au substrat;

- Il permet des applications de – 5°C (+23°F) jusqu’à 37°C (+98°F);

- Une bonne résistance à l’impact;

- Il permet au produit de résister au brouillard et à la pluie, 90 min. après application;

- Une résistance à l’abrasion de très haute performance;

- Il permet l’application sans qu’on doive tenir compte du point de rosée (hygroréactif);

- Une résistance supérieure aux hydrocarbures et aux milieux salins;

- Préparation de surface minimale;

- Grâce à sa formule mono composant le produit est facile à mélanger;

- Il apporte une résistance aux milieux avec pH situé entre 5.5 et 12 .5;

- Il permet au zinc de rester longtemps en suspension, une fois mélangé;

- Il permet au produit d’être utilisé sans couche de finition;

- Facile d’application avec tous les équipements standards de peinture, pistolet ou airless.

Chlor-Rid

- Éliminer les chlorures, sulfates, nitrates et autres contaminants salins solubles.

- Ne laisse aucun film ou résidu après utilisation.

- Biodégradable, hydrosoluble, non toxique.

Disponible dans plusieurs magasins Sherwin-Williams.

Site web: https://chlor-rid.com/index.php/chlorrid-francais/

HoldTight® 102

- Prévenir l’apparition de rouille sur les surfaces sablées par grenaillage sec ou humide.

- Élimine tous les sels de surface.

- Biodégradable, hydrosoluble, non toxique.

Site web: https://holdtight.com/products/holdtight-102/

(clients Américains)

Hold*Blast

- Passive les surfaces pour empêcher l’apparition de rouille naissante.

- Prévenir l’apparition de rouille sur les surfaces sablées par grenaillage sec ou humide.

- Biodégradable.

- Sans danger pour l’environnement

Sherwin-Williams #8714

2525 RUE WATT LOCAL 1

SAINTE-FOY, QC G1P3T2 CAN

PHONE: 418 656-6505

FAX: 418 656-4290

Site web: https://chlor-rid.com/index.php/holdblast-surface-passivator/

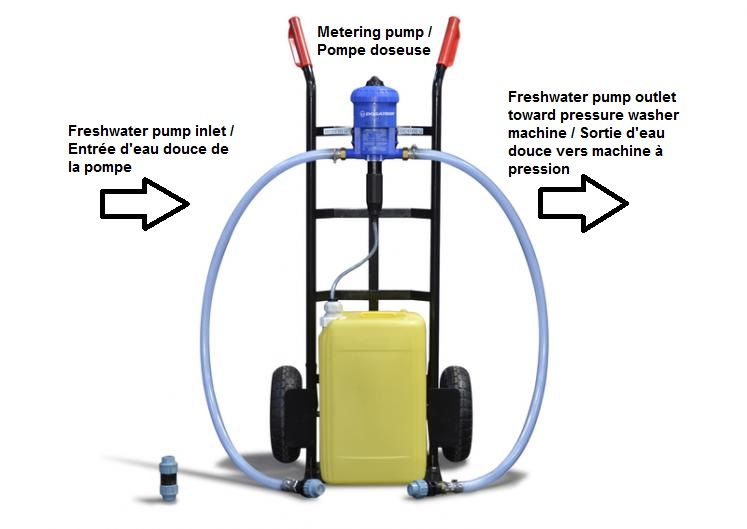

Pompe doseuse |

|

| Plus d’information |

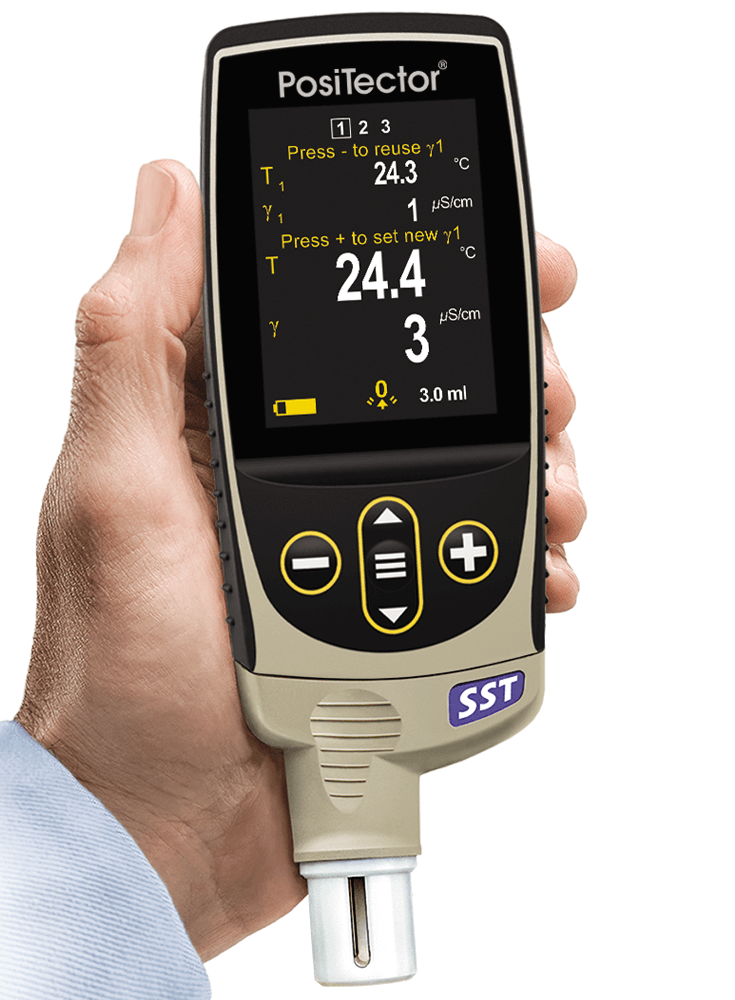

Test de sel |

|

| Plus d’information |

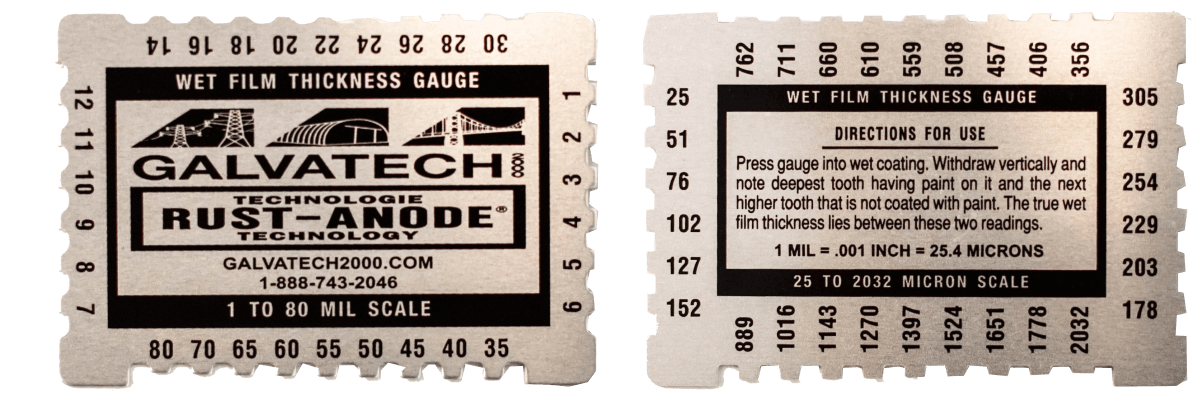

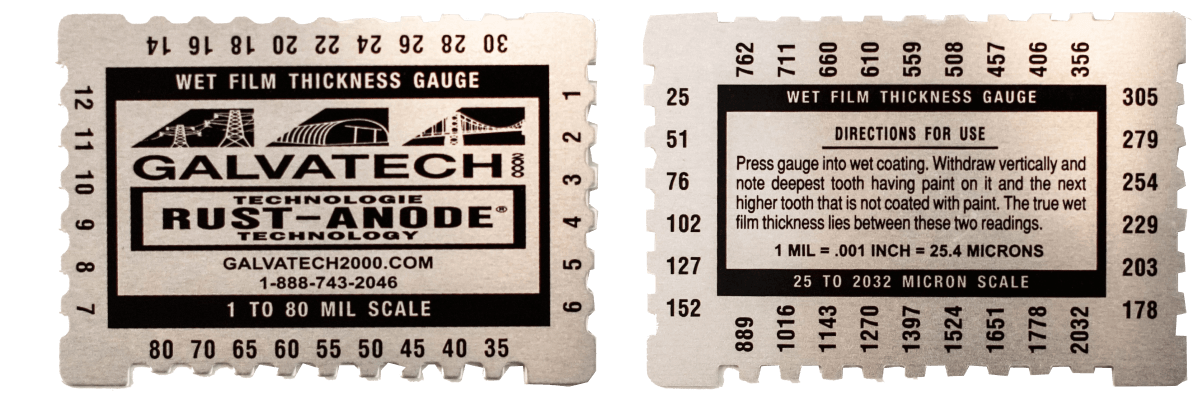

Wet gage et Gauge électronique

| Wet gage : sert à mesurer l’épaisseur humide du produit appliqué. |

| Gauge électronique : sert à mesurer l’épaisseur sec du produit appliqué. | |

|   |

Tableau comparatif

Questions et réponses

Oui, Rust-Anode est homologué pour recharger la protection en zinc de structures d’acier galvanisé à chaud ou de la métallisation. De plus, notre produit est homologué par le Ministère du Transport du Québec, de l’Ontario et du Canada, en plus d’être approuvé par Hydro-Québec (SN31.101 pour la maintenance des postes de distribution et TET-LIA-N-SUP0012 pour la maintenance des pylônes).

Rust-Anode offre une durée de vie comparable à la galvanisation à chaud ou à la métallisation dans les mêmes conditions d’exposition.

Ponts, maritime, tours de transmission électrique et ou de télécommunication, bâtiments, réservoirs, transport, camions-remorque, usine.

Parlez à un expert reconnue par l'ordre des ingénieurs du Québec

Notre équipe hautement qualifiée certifiée NACE/AMPP saura répondre à vos questions techniques, en travaillant en équipe avec vous ou votre client nous allons vous aider à trouver la cause de vos problèmes de rouille et ou de corrosion, trouver la bonne solution pour effectuer les réparations, émettre un protocole sur mesure incluant les préparations de surfaces, les méthodes d’application et le contrôle qualité.