Our products

Our products offer comparable lifespan performance to that of hot-dip galvanization under the same environmental conditions.

The benefits of Rust-Anode technology.

- Acts as an active coupling with steel and creates an electrochemical bond that provides active protection (mV) in the same range as hot-dip galvanization or metallization.

- Provides genuine active and sacrificial protection, similar to hot-dip galvanization.

- Exposure to temperatures ranging from -62°C to +120°C (-80°F to +250°F).

- Dries in humidity without restriction of the dew point.

- No substrate distortion effects compared to hot-dip galvanization.

- Weldable.

- Fast drying.

- High flexibility.

- Can be coated with most paints, including powder coatings.

- Successfully tested for toxicity under fire.

- The zinc thickness can be controlled during or after application, with additional layers if needed.

- Extra-fine atomized pure zinc (purity of 99.995%) enables higher zinc density and a high-performing anode.

Learn more about Rust-Anode®

One of our experts will contact you to assist you.

Select your application area to learn more about our products.

Rust anode® primer

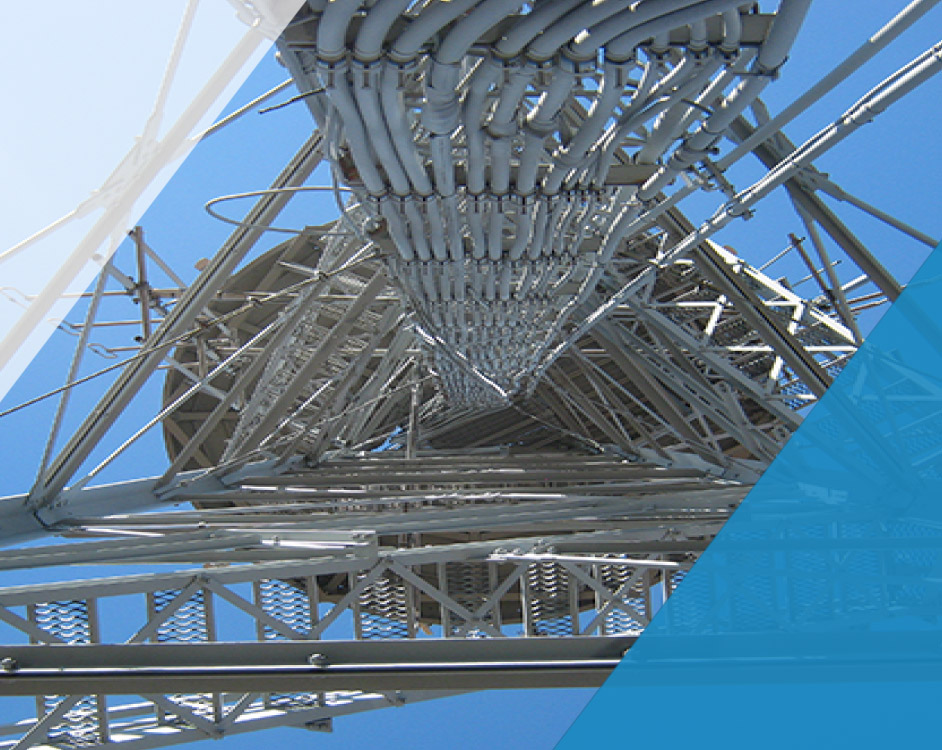

Since 1954, RUST-ANODE® products have been recognized and used in over 50 countries! Their superior characteristics have placed them at the forefront of anti-corrosion solutions. Approved by leading official laboratories in Europe and adopted by NATO forces from the very beginning, RUST-ANODE® technology has established itself as a global leader in providing active protection and extending the lifespan of everyday assets.

Questions and answers

Yes, Rust-Anode is approved for replenishing the zinc protection of hot-dip galvanized steel structures or metallization. Additionally, our product is approved by the Ministère du Transport du Québec, Ontario, and Canada, as well as being approved by Hydro-Québec (SN31.101 for maintenance of distribution stations and TET-LIA-N-SUP0012 for maintenance of pylons).

Rust-Anode offers a comparable lifespan to hot-dip galvanization or metallization under the same exposure conditions.

Bridges, maritime structures, electrical and telecommunication transmission towers, buildings, tanks, transportation, trailers, and factories.

Free Training

A free training/presentation (1 or 2 hours) on steel and zinc corrosion. A certificate of completion is available upon request.