Galvatech 2000 is recruiting a business development manager.

Galvatech 2000 is seeking a Business Development Manager to play a key role in its growth in Quebec and internationally. If you have strong experience

In a world increasingly aware of environmental challenges, sustainability has become a priority for many businesses and industries. Circular economy principles are emerging as an innovative approach to promoting sustainability by minimizing resource waste. Companies are adopting preventive maintenance practices and structural health monitoring to ensure the longevity of their infrastructure while reducing environmental impact.

Innovation is essential to address these challenges. Teams of experts, including research chemists and sustainability specialists, are pushing technological boundaries. Together, they develop cutting-edge solutions such as Rust-Anode technology, an advanced corrosion protection process.

This high-performance coating is based on the principle of cathodic protection, preventing rust formation on metal structures. This unique approach significantly extends the lifespan of equipment, reducing the need for frequent maintenance and replacement. It’s an effective alternative to hot-dip galvanization.

In a rapidly evolving sector, innovation and collaboration between businesses and experts are key to tackling sustainability challenges. With technologies like Rust-Anode and preventive maintenance practices, companies can enhance operational efficiency while conserving natural resources for future generations. By adopting circular approaches, industries can position themselves as responsible players and inspire positive change for our planet’s future.

$70.2

Billion

A 2021 study conducted by AMPP (Association for Materials Protection and Performance) estimated the annual cost of corrosion in Canada at CAD 70.2 billion. This staggering figure highlights the economic burden of corrosion and the critical importance of prevention in infrastructure and industrial equipment.

Corrosion can severely impact the safety, reliability, and durability of structures and equipment, as well as the environment. Implementing effective prevention measures is crucial to minimize these impacts.

With our expertise across several related fields, we can assist you from the design phase based on your client’s requirements. Several critical factors—such as usage, environmental exposure, metal types, surface preparation, and quality control—are essential to achieving performance and longevity, aligning with sustainability goals.

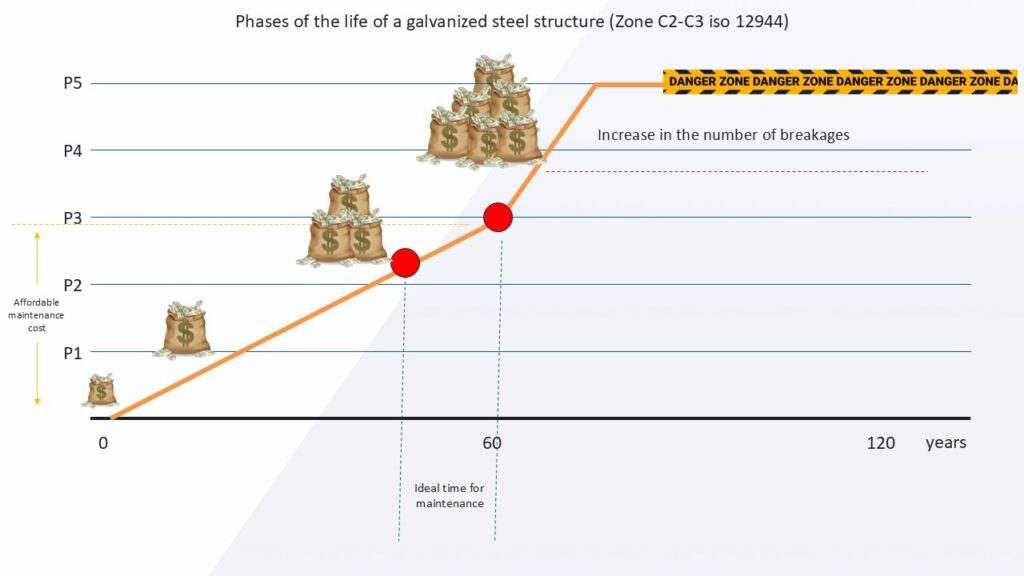

Too often, we are called upon when it’s already too late. Design flaws that accelerate rust or corrosion development are a frequent challenge. Additionally, asset inspection and maintenance are often neglected due to poor planning or limited budgets. With our unique technology, equivalent to hot-dip galvanization, we can offer duplex systems with enhanced lifespan. To help you better understand the challenges and prevent future issues, we provide a free, in-depth training session covering all these concepts.

Our Unique Technology;

The Rust-Anode® technology allows for on-site zinc recharging of new or used structures damaged by rust or corrosion and offers the same performance as hot-dip galvanization.

Galvatech 2000 is seeking a Business Development Manager to play a key role in its growth in Quebec and internationally. If you have strong experience

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

In 2024, Trifluvienne Pneus & Mécanique SL turned to Galvatech 2000 to extend the service life of their galvanized metal roof, which had been in