The Importance of a Clear Specification:

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

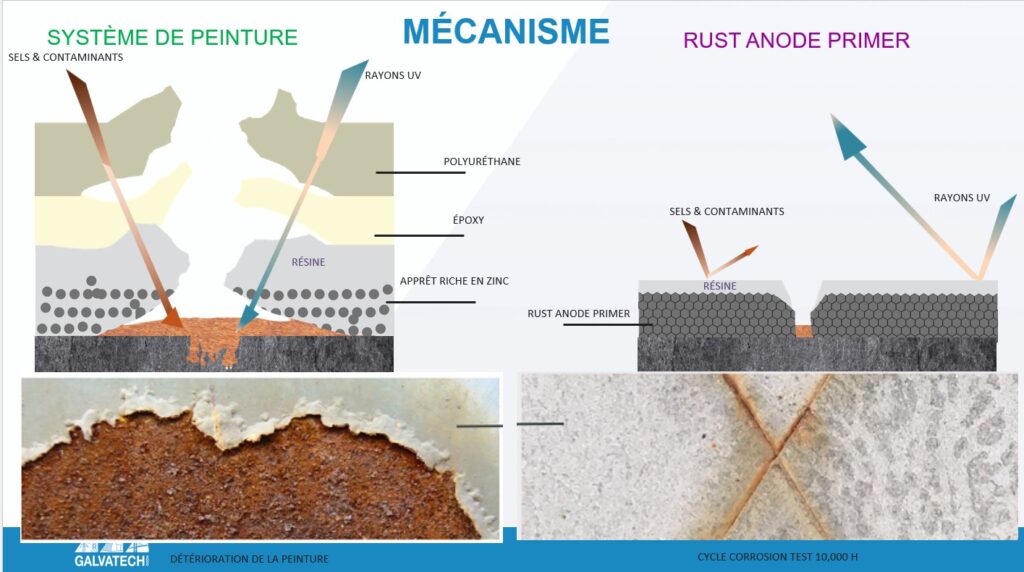

Corrosion is a formidable enemy of metal structures, capable of weakening buildings, bridges, and other critical infrastructures. It leads to costly repairs and poses potential hazards. Fortunately, an effective and long-lasting solution is available: Rust-Anode Primer, which offers much more than just a protective barrier.

Rust-Anode Primer is designed to deliver precisely what you expect: optimal protection against corrosion with a simple and quick application process. For customers, it’s not just a solution but a factual enhancement of their infrastructure’s durability. With its superior performance, this solution offers benefits such as reduced maintenance and increased durability and proves to be more cost-effective in the long term.

The high 99.995% pure organic zinc content in Rust-Anode Primer ensures superior cathodic protection by forming an electrochemical bond with the metal. Unlike simple anti-corrosion paints, this product offers active protection, even if the coating is damaged, thanks to the zinc that continues to protect the underlying metal.

With technical support provided by AMPP/NACE-certified experts in corrosion and coatings, Galvatech ensures that every customer receives the necessary guidance for a successful application. Our team is present from the project’s initial stages and remains available throughout the process, ensuring a smooth and stress-free customer experience.

Critical Points for Decision-Making:

– Cathodic Protection vs. Passive Protection:

– Rust-Anode Primer provides direct cathodic protection, ensuring the metal remains protected even if the coating is damaged, unlike standard paints, offering only a physical barrier.

– Durability and Maintenance:

– With durable protection and significantly reduced maintenance costs, Rust-Anode Primer stands out as the ideal solution to extend the lifespan of structures for several decades.

– Application and Flexibility:

– Rust-Anode Primer is easy to apply with standard equipment such as brushes, rollers, or spray equipment. It requires minimal surface preparation, making it ideal even for large-scale projects.

– Cost and Efficiency:

– With a competitive initial investment compared to traditional paints, Rust-Anode Primer stands out for its high performance and low maintenance needs, making it a durable and advantageous long-term choice.

Unique Features of Rust-Anode Primer:

– No mixing is required; the single-component coating is easy to apply.

– Lower VOCs than the strictest U.S. standards (California).

– Easy to apply with standard painting equipment, including electrostatic.

– Requires minimal surface preparation.

– Can be applied on non-friable rust.

– Can recharge zinc on existing hot-dip galvanization or metallization.

– Can be overcoated with most paints.

– Resistant to hydrocarbons like hydraulic oil, diesel, gasoline, and oil.

– Dries very quickly in humidity.

– High resistance to saltwater and saline environments.

– It can be applied to aluminum and stainless steel without sanding after minimal cleaning.

Conclusion:

In summary, preventing corrosion is essential to ensure the longevity and safety of metal structures. By using zinc-rich compounds like Rust-Anode Primer, you can effectively protect your projects against the harmful effects of corrosion. Choosing a suitable anti-corrosion coating is crucial to distinguish between a durable structure and one prone to corrosion problems. With its unique features and high zinc content, Rust-Anode Primer offers a comprehensive and reliable solution for your corrosion protection needs for decades to come.

The Rust-Anode® technology allows for on-site zinc recharging of new or used structures damaged by rust or corrosion and offers the same performance as hot-dip galvanization.

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

In 2024, Trifluvienne Pneus & Mécanique SL turned to Galvatech 2000 to extend the service life of their galvanized metal roof, which had been in

A sheet pile wall was installed for a new development project adjacent to a train yard. Covering approximately 22,000 square feet, the project team chose