The Importance of a Clear Specification:

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

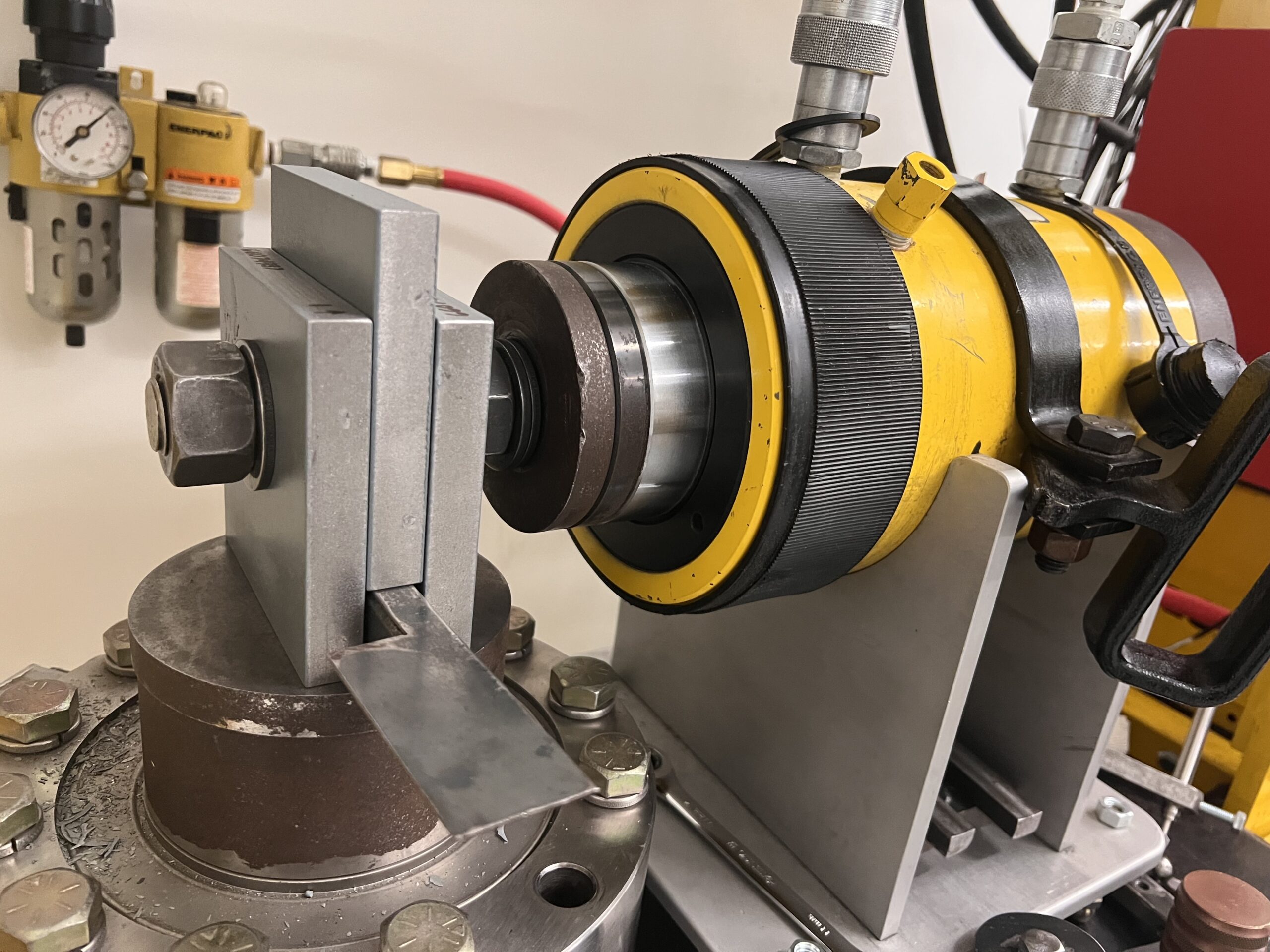

We are delighted to have successfully passed the test for Slip Coefficient and Resistance to Tension Creep Resistance criteria for use on faying surfaces with the Rust-Anode Primer in accordance with the ‘’Research Council on Structural Connections’’ (RCSC)

In the world of structural engineering, the integrity of bolted connections is preeminent, ensuring the stability of bridges, buildings, and various structures. One critical aspect often overlooked is the coating applied to faying surfaces, where structural members join.

Coated faying surfaces prevent corrosion and rust bleeding, but their slip resistance is crucial for withstanding the fatigue caused by loading and unloading cycles, such as vehicles traversing a bridge deck.

The Specification for Structural Joints Using High Strength Bolts is published jointly by the American Institute of Steel Construction (AISC) and the Research Council on Structural Connections (RCSC). While the ten sections of the specification provide limited coverage on the testing of coatings in bolted joints, Appendix A, titled “Testing Method to Determine the Slip Coefficient for Coatings Used in Bolted Joints,” delves into this aspect with four dedicated sections: General Provisions, Test Plates and Coating of the Specimens, Slip Tests, and Tension Creep Tests.

There are four crucial and essential variables for testing coating slip coefficients. These include cure time, special curing procedures, maximum coating thickness, and coating composition.

The slip coefficient is calculated based on the mean slip load, and tension creep testing follows if slip coefficient testing produces acceptable results. Once the coating passes both tests, it receives a classification (Class A, B, or C) based on slip coefficient values. A Certificate of Testing accompanies the test report, listing essential variables and providing crucial information for coating application.

The Rust-Anode® technology allows for on-site zinc recharging of new or used structures damaged by rust or corrosion and offers the same performance as hot-dip galvanization.

Prepare, Apply and Control with Precision In the coatings industry, a clear specification is far more than a simple costing tool. It is a true

In 2024, Trifluvienne Pneus & Mécanique SL turned to Galvatech 2000 to extend the service life of their galvanized metal roof, which had been in

A sheet pile wall was installed for a new development project adjacent to a train yard. Covering approximately 22,000 square feet, the project team chose

Galvatech

304, rue Plourde

St-Leon le Grand, (Quebec)

Canada G0J 2W0

Phone : 418 743-2046

Toll-free : 1 888 743-2046